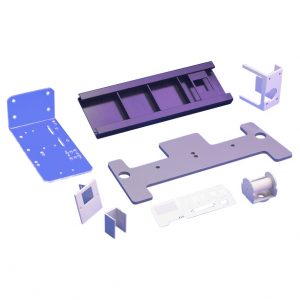

Design and production of plastic parts

To guarantee maximum responsiveness and the shortest possible lead times, REVOLUPLAST designs and produces all its bespoke plastic parts by machining them before make them in volume (by folding or bending).

REVOLUPLAST is equipped with recent CNC machining centers and a high-performance machining and cutting workshop, including 3-axis milling and laser cutting stations, combined with our CAD-CAM workstations..

This allows us not only to produce all types of sub-assemblies by plastic working to manufacture plastic housings or casings, bespoke plastic terminals or claddings. We can also machine plates, front panels and faceplates, and design supports or mounts or bespoke cut plastic parts to size from thermoplastic sheets as well as accessories for professional furnitures.

Likewise, plastic mounts or insulating enclosures for electrical or electronic equipment can be produced quickly. This manufacturing principle is also well suited to certain displays or technical parts in the POS field.

These plastic parts do not require tooling or moulding of plastic parts, making it easy to respond to requests for small and medium production runs (a few dozen to several thousand units per launch) without heavy investment.

One of the first essential manufacturing stages in our process is the machining our ABS, PS, PC, PMMA (Plexi) or PVC sheets usually in thicknesses of between 2 and 20 mm, within good tolerances.

To ensure greater responsiveness, a large stock of thermoplastic sheets is available on our site. Different batch-dyed colours are available and, failing this, paint and varnish coatings can be applied by our paint shop for various uses and finishes.

Marking too, whether by silk-screen printing or digital printing, is performed on site and offers numerous options in terms of customisation with the aid of our designer.

For the most complex plastic parts and in larger dimensional volumes, we work with SolidWorks software; DXF, DWG, IGS, STP, STL and AI type 2d and 3d formats can be used by our design office.

Revoluplast also means:

plastic working - plastic enclosures - plastic electronics enclosures - plastic housings - plastic machining - plastic boilermaking - no-mould plastics manufacturing