Depending on the complexity of your project, the production of your part will be comprised of several stages.

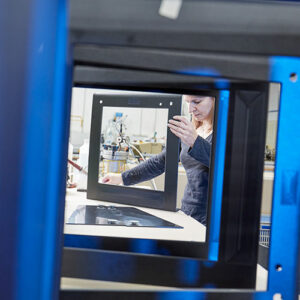

Qualification prototype for approval

To approve creation or modification of your plastic part, you will be provides with a validation prototype.

This allows you to test the integration of its content and to check that it meets your specifications.

Produced on the same machining centres as forthcoming runs, it is a faithful version of the parts that will follow and will serve as a reference for future production speeds.

Plastic enclosure manufatured by plastic machining

REVOLUPLAST has a broad and constantly evolving range of machines, suited to the specific implementation conditions of each project:

- CNC milling

- Laser cutting for acrylic materials

Folding and hot bending of plastic enclosure to create volume

To enable you to obtain high-quality plastic parts and enclosures.

We have heat bending machines allowing us to produce complex assemblies.

We work on the shapes and contours of our plastic parts after they have been machined and marked.

Assembly and gluing custom made plastic enclosures

Because each project is unique, these steps, most of which are carry out manually are performed in our workshops by people with unique expertise.

Each component of enclosures is assembled with a machined reference for reproducible positioning and reinforced welding.

Accessories integration

REVOLUPLAST supplies and integrates a wide range of accessories into its plastic enclosures products including:

- Screws, inserts, small columns, locks, hinges, handles, adhesive feet, seals, DIN rail clips, etc.

- Transparent windows or infra-red filters.

- Membrane or flexible keyboards, Lexan, adhesive labels, resin domes.

Packaging and logistics

For all your individual and bulk packaging requirements,our shipping department offers the best packaging solutions, ensuring perfect transport.

Revoluplast also means:

plastic working – plastic enclosures – plastic electronics enclosures – plastic housings – plastic machining – plastic boilermaking – no-mould plastics manufacturing