Production of plastic cladding

Our plastic working and small-scale boilermaking experience allows us to create the cladding for your dynamic POS with no moulds.

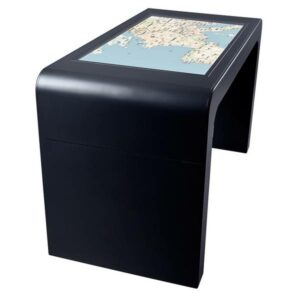

Plastic can be used to cover touchscreen tables, touchscreens or mini counter terminals, which can also be mounted on a metal framework or structure for larger items; making the whole unit considerably lighter.

Plastic cladding for your systems will make them easier and definitely less expensive to transport.

Our design department will suggest ideas and give you some tips on how to design the cladding and its assembly.

Wether it's for dynamic POS, for customised terminals or communication tools, we are able to propose and design the front of the digital display section. The plastic casing for the whole unit or sub-assemblies such as the custom-made plastic casing for coin mechanism or the plastic casing for the electronics.

Our experience of these applications, using various POS screen models, means that after gathering all the elements of your project and specifications. We can offer you technical solutions and also a preliminary design study providing a 3D rendering before physical design a qualification part..

In addition, we produce series from ten or more units, and sometimes, even ust a few units if they are recurrent.

Whether this is for self-service access terminals, for self-service checkouts in shopping center, bespoke products for medical applications or dynamic POS displays for communication or information media in public places.

Our strengths :

- Design from a drawing or from a model or specifications

- To your measurements (from 20 cm³, to 2 or 3 m³)

- An aesthetically pleasing terminal that can be easily tranported

- Customisable with finishes using marking or painting

- Allows radio waves to pass through for your wireless and RFID components

- Series production from ten or more units

- Runs of 20 to 500 parts can be produced within 3 to 5 weeks

- Low initial investment

- Great flexibility in the event of changes or modifications

- Flexibility and responsiveness, production from 3 to 4 weeks

Options :

- Design approach before conception

- Marking by digital or silk-screen printing

- Application of paints and varnishes

- Internal metallization if necessary to improve the EMC

- Choice of ABS, high impact PS, PVC, PMMA (Plexi), PC, etc. materials from a thickness of 3 to 10 mm

- Fire-protection treatment (UL94HB or V0, occasionally M1 or M2)

- Range of accessories: inserts, screws and bolts, hinges, feet, castors, faceplates, etc.

Revoluplast also means:

plastic working - plastic casings - plastic electronics casings - plastic housings - plastic machining - plastic boilermaking - no-mould plastics manufacturing